which of the following is a type of machine safeguarding osha 10

Which of the following is a type of machine safeguarding. Avoids creating additional hazards.

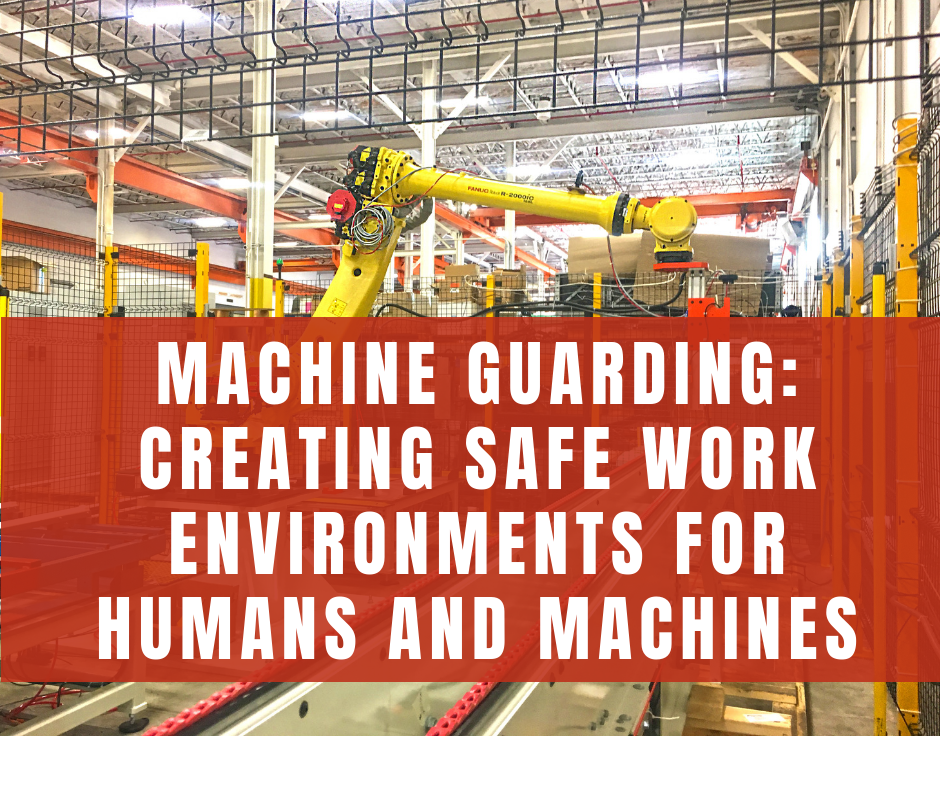

Machine Guarding Creating Safe Work Environments For Humans And Machines

The Occupational Safety and Health Administrations OSHAs requirements for machine guarding are found in 29 Code of Federal.

. Machine Guarding OSHA 10-Hour Outreach Training General Industry. Which of the following is a type of machine safeguarding. Commonly Used Machine Guards 12 Table 2.

Primary methods Guards Devices. Punching action results when power is applied to a slide ram for the purpose of blanking drawing or stamping metal or other materials. The following are all machine safeguarding requirements except.

All machines consist of three fundamental areas the point of operation the power transmission device and the operating controls. All machines consist of three fundamental areas the point of operation the power transmission device and the operating controls. Moving machine parts have the potential to cause severe workplace injuries such as crushed fingers or hands amputations burns or blindness.

Machine Guarding OSHA 10-Hour Outreach Training General Industry. The following are all machine safeguarding requirements except. Power transmission apparatus which feeds energy to machines.

Controls or attachments that prevent inadvertent access by employees to hazardous machine areas. Primary machine can fill in as. Use iAuditor to take photos of identified issues and immediately generate a report for review and corrective action.

A good machine safeguarding system eliminates the possibility of the operator or another worker placing parts of their bodies near hazardous moving parts. Safeguards are essential for protecting workers from these preventable injuries. One basic form of machine guarding is called guarding by location According to OSHA this involves positioning or designing a machine so that the hazardous parts are away from areas where employees work or walk or alternatively installing enclosure walls or fences that restrict access to machines.

_____ True or False. This problem has been solved. What are the 2 types of primary safeguarding methods.

Presence sensing safety trip controls two hand control pull back restraint. Which of the following is an example of a safeguarding device. Which types of moving parts need guarding.

We can group machine safeguards under five general classifications. The following types of mechanical components present amputation hazards. When you are protected by the with you opera ng the machine safeguards and others in the work 1.

Moving parts which are part of the machine or bigger system. OSHA Safety and Health Information Bulletin SHIB January 25 2013. Primary Safeguarding Methods Two primary methods are used to safeguard machines.

Types of Machine Guarding Restraint Devices. Machine guarding and related machinery viola-tions continuously rank among the top 10 of OSHA citations issued. Any machine part function or process that may cause injury must be.

According to OSHA One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point of operation ingoing nip points rotating parts flying chips and sparks The following are some key OSHA requirements for machine guarding according to. Which of the following is a type of machine safeguarding punching. An employee trained on his you can take it off as long as you area are protected also you are.

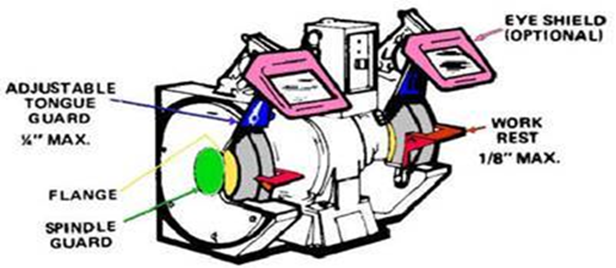

If a new guard causes interference 4. 2 Fixed limited access guards. A fixed guard is a simple device attached to the machine designed to cover hazardous mechanical motions and prevent entry from hands or fingers.

Prevents employee contact with the hazard area during machine operation. Machine safeguarding helps protect workers from preventable injuries in all three areas. Feeding and ejection methods is a type of machine safeguarding.

There are several mechanical motions that pose risks to workers. Machine guarding is basically guarding or protecting machine parts that are the most dangerous. OSHA states that mechanical hazards are most likely to occur in three major areas.

Also asked is punching a type of machine safeguarding. The point of operation from where all the work is performed. To the basic concepts and principles for machine safeguarding as described by OSHA in 1910 Subpart O Machinery and machine guarding.

Herein what are the most common types of machine guarding. These include moving belts arms. This OSHA machine guarding checklist is used for evaluating the preparedness of operators when handling machines.

This OSH Answers fact sheet is based. It does not specify all machine guarding requirements or all types of machinery or equipment. Machine Guarding OSHA 10-Hour Outreach Training General Industry.

According to OSHA One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point of operation ingoing nip points rotating parts flying chips and sparks The following are some key OSHA. Various types of machine guards available for machine guarding. It may stop the machine if a hand or any part of the body is inadvertently placed in the danger area.

Replace it at the end of the shi L. Guards are barriers which prevent access to danger areas. The most common types of machine guards are.

Types of Machine Safeguards Safeguarding machinery. The machine guard must prevent hands arms and any other part of a workers body from making contact with dangerous moving parts. Criteria for Machine Safeguarding.

Guards and some types of. It also covers the inspection of the machine guards to ensure that it is securely placed and anchored. A safety device may perform one of several functions.

Criteria for Machine Safeguarding. Good to operate. Simply so what are the most common types of machine guarding.

Both types of safeguards need to be properly designed constructed installed used and maintained in good operating condition to ensure employee protection. There are four general types of guards and well discuss them in the next section.

Machine Guarding Named To Osha S Top Ten Violations List For 2021 The National Provisioner

What Is Machine Safeguarding T P Supply Co

Osha Machine Guarding Requirements And Compliance Checklist Arauniversity Org

2021 Top 10 Osha Violations Machine Guarding 2022 01 25 Ishn

Machine Guarding Named On Osha S Top 10 Violations In 2019 Quality Assurance Food Safety

Kpa Osha Machine Guard Requirement Compliance Checklist

Machine Guarding Approach Management Services

Osha 2045 Machinery And Machine Guarding Standards Chesapeake Region Safety Council

Crane Balancing Act Truck Cranes Crane Construction

Osha Standards For Industrial Companies Industrial Safety Osha Safety Training Health And Safety Poster

Machine Guarding 101 The Basics Kha Online Sds Management

Top Questions When Selecting Machine Guarding Wirecrafters Blog

Machine Guarding Best Practices Occupational Health Safety

Machine Guards Eliminate Hazards For Employees Article The United States Army

Machine Guard Safety Training From Safetyvideos Com Youtube

Williams 12 X 3 4 Drive Impact Extension 6 113 In 2022 Schuylkill County Driving Valley View